Pressure 6 click

Although the internal pressure sensing element is thermally compensated, the thermal readings are also available on a separate 16-bit register. The conversion data can be either stored on the internal FIFO buffer or directly accessed over the I2C interface. The BM1386GLV offers an IIR filtering, which allows further signal conditioning and increased accuracy.

The BM1386GLV sensor requires a low number of external components, allowing a very compact design. Therefore, an additional I2C level translator is used on the Pressure 6 click, expanding its connectivity options to a much wider range of microcontrollers (MCUs). Features such as the long-term stability, linearity, and good reproducibility, are achieved by employing very advanced piezo-resistive micromachining processes so that the sensor can be used for development of the industry-related applications, as well as in the healthcare applications, mobile devices, smartphone applications, and similar.

How does it work?

The main component of the Pressure 6 click is the BM1386GLV, a pressure sensor IC, produced by ROHM Semiconductor company. This is a highly integrated piezo-resistive absolute pressure sensor, with some advanced features, such as the thermal compensation of the pressure micro-electromechanical sensing element (MEMS), signal conditioning by the embedded IIR filtering section, and a FIFO buffer. The FIFO buffer has 32 slots for storing the data from both the thermal and the pressure sensor. The FIFO buffer can be disabled if the application needs to read the data directly. The interrupt pin DRI can be configured to alert the host MCU about the FIFO full buffer, FIFO watermark threshold exceeded event, and Data Ready event. The DRI is configured as an open-drain output pin, pulled up by a resistor on the Pressure 6 click. The presence of DRI pin allows more efficient firmware to be written, saving the host MCU from constantly having to poll the status register. The DRI pin is routed to the mikroBUS™ INT pin.

The pressure readings are stored in three pressure registers, while the temperature readings are stored in two thermal registers. The pressure data is 20 bits long, while the thermal data is 16 bits long. The same 16-bit A/D converter is used for both sensors, but the readings from the pressure sensor are further conditioned by the on-chip signal processing section. After the conversion interval is completed, the RD_DRDY bit will indicate that there is data ready for reading on the respective output registers. Once this bit has been read, it will be reverted to 0, waiting for a new conversion interval to be finished. The state of this bit can be redirected to the DRI pin, allowing an interrupt event to be triggered on a host MCU, whenever there is new data available.

The conversion data is available over the I2C interface, as mentioned before. The I2C bus lines (SDA and SCL) are routed to the respective I2C mikroBUS™ pins which are pulled up by resistors on the Click board™ itself, allowing the Click board™ to be used right out of the box. The datasheet of the BM1386GLV IC offers conversion formulas which can be used to convert the raw binary values from the respective registers to physical, human-readable format. However, Pressure 6 click comes with the library that contains functions which output properly formatted thermal and pressure readings.

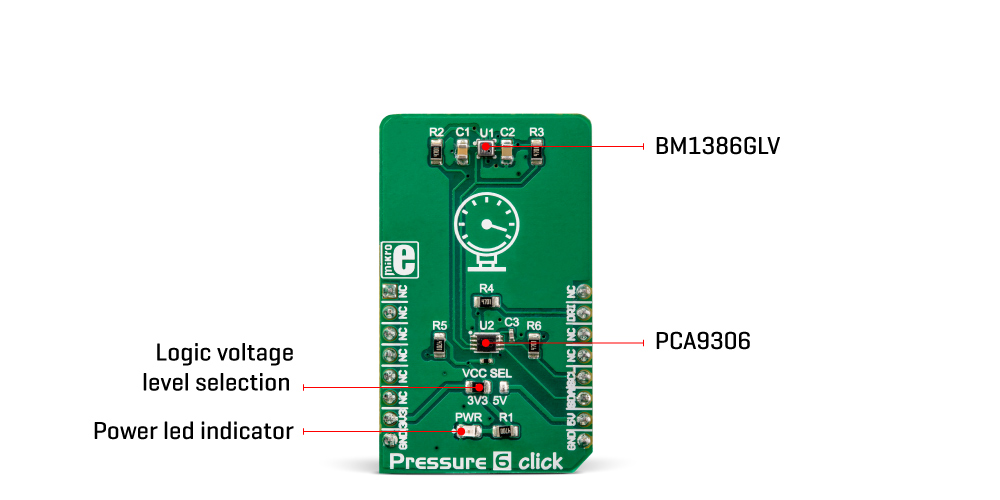

In addition to the BM1386GLV IC, Pressure 6 click incorporates an additional IC. It is the PCA9306, a well-known bi-directional I2C level translator from Texas Instruments, used on many different Click board™ designs, due to its simplicity and reliability. Since the BM1386GLV IC is limited to 3.3V operation, this IC allows it to be used with 5V too, expanding the connectivity of the Pressure 6 click to MCUs which use 5V levels for the I2C communication. The logic voltage level selection can be made by switching the small onboard SMD jumper labeled as VCC SEL, to a proper position (3V3 or 5V).

Specifications

| Type | Pressure |

| Applications | It can be used for weather stations, mobile devices, healthcare devices, but also for development of industrial-related applications |

| On-board modules | BM1386GLV, a pressure sensor IC, produced by ROHM Semiconductor company; PCA9306, a bi-directional I2C level translator from Texas Instruments |

| Key Features | Very accurate pressure and temperature readings, on-chip IIR filtering and data conditioning, thermal compensation of the internal MEMS sensor, it can be used with the wide range of different microcontrollers, both operating with 3.3V and 5V communication levels |

| Interface | I2C |

| Input Voltage | 3.3V,5V |

| Click board size | M (42.9 x 25.4 mm) |

Pinout diagram

This table shows how the pinout on the Pressure 6 click corresponds with the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

Onboard jumpers and settings

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | - | Power LED indicator |

| JP1 | VCC SEL | Left | Logic level voltage selection: left position 3.3V, right position 5V |

Pressure 6 click electrical specifications

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Pressure range | 300 | - | 1300 | hPa |

| Pressure measurement resolution (absolute / relative) | -0.12 / -1 | - | +0.12 / +1 | hPa |

| Temperature range | -40 | - | +85 | ˚C |

| Temperature measurement resolution | -2 | +2 | ˚C |

Software support

We provide a library for the Pressure 6 Click on our LibStock page, as well as a demo application (example), developed using MikroElektronika compilers. The demo can run on all the main MikroElektronika development boards.

Library Description

The library initializes and defines the I2C bus driver and drivers that offer a choice for writing data in register and read data from register. The library includes function for read Temperature data and Pressure data. The user also has the function for power ON and porew OFF procedure and function for reads Interrupt state.

Key functions:

uint16_t pressure6_getPressure()- Functions for read Pressure data

- uint8_t pressure6_getTemperatre() - Functions for read Temperature data

- void pressure6_powerON() - Power ON procedure

Examples description

The application is composed of the three sections :

- System Initialization - Inicializes I2C module and set INT pin as INPUT

- Application Initialization - Initialization driver init and start power ON procedure for wake up chip and sets measurement mode.

- Application Task - (code snippet) - Read Pressure data and Temperature data and logs data to USBUART every 1 sec.

void applicationTask()

{

pressure6_waitingForNewData();

Pressure = pressure6_getPressure();

Temperature = pressure6_getTemperatre();

// Logs Pressure and Temperature data

IntToStr(Pressure, demoText);

mikrobus_logWrite(" Pressure : ", _LOG_TEXT);

mikrobus_logWrite(demoText, _LOG_LINE);

IntToStr(Temperature, demoText);

mikrobus_logWrite(" Temperature : ", _LOG_TEXT);

mikrobus_logWrite(demoText, _LOG_LINE);

mikrobus_logWrite(" ", _LOG_LINE);

Delay_ms( 1000 );

}

The full application code, and ready to use projects can be found on our LibStock page.

Additional notes and information

Depending on the development board you are using, you may need USB UART click, USB UART 2 click or RS232 click to connect to your PC, for development systems with no UART to USB interface available on the board. The terminal available in all MikroElektronika compilers, or any other terminal application of your choice, can be used to read the message.

mikroSDK

This click board is supported with mikroSDK - MikroElektronika Software Development Kit. To ensure proper operation of mikroSDK compliant click board demo applications, mikroSDK should be downloaded from the LibStock and installed for the compiler you are using.

For more information about mikroSDK, visit the official page.

Downloads

mikroBUS™ Standard specificationEnter the code in the box below: