Power Distribution Board for Romi Chassis

This power distribution board is designed specifically for the Romi chassis as a convenient way to access the chassis’s battery power and pass that on the rest of the electronics that make up your robot. It has slots for soldering directly to the chassis’s battery contacts offers reverse voltage protection, several power switching options, and easy access to the various power busses. Just add your own motor drivers, microcontroller, and sensors to complete your Romi robot.

This power distribution board is designed specifically for the Romi chassis as a convenient way to access the chassis’s battery power and pass that on to the rest of the electronics that make up your robot. The board features reverse voltage protection and the patented latching circuit from the Pololu pushbutton power switch, providing a compact, solid-state power switch for your robot that can be controlled with a momentary pushbutton: one push turns on power and another push turns it off.

The board has a small pushbutton already installed and offers convenient points for connecting external pushbutton or tactile switches in parallel. It also offers several alternate pushbutton connection options that result in push-on-only or push-off-only operation, and additional inputs enable further power control options like allowing your robot to turn off its own power. Alternatively, the board can be reconfigured to disable the pushbutton circuit and give control to the small installed slide switch.

The board’s power buses are accessible through a set of 0.1″-spaced pins that are compatible with standard 0.1″ male and 0.1″ female headers, and also through a larger set of holes that are compatible with 3.5mm-pitch terminal blocks (you can combine a 2-pin block and a 3-pin block into a single 5-pin block that spans the three power holes and two ground holes).

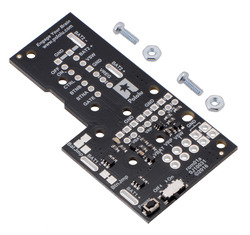

Two 1/4″ #2-56 screws and two #2-56 nuts are included for mounting the board to the Romi chassis.

For an alternative to this board that has all the same functionality and adds dual motor drivers and a powerful switching step-down voltage regulator, see the Motor Driver and Power Distribution Board for Romi Chassis.

|

|

Installing the power distribution board

|

|

- Make sure the Romi chassis battery contacts have been installed in the chassis. The four single contacts should all have solder tabs that protrude through the holes in the top of the chassis. Note: these four battery contacts should have been dropped into the chassis through the openings in the top, which leaves them loosely resting in their slots; this will give you the option to later remove the power distribution board and battery contacts from the chassis as a single piece after soldering.

- Line up the four slots in the board with the chassis’s four battery contact solder tabs and then screw the board to the chassis using the two included screws and nuts.

- Solder the four contacts to the board. We recommend not having batteries installed in the chassis while you do this as they can act as heat sinks that make it more difficult to solder. The battery terminal slot in the PCB should be completely filled with solder, as shown in the right picture above.

Using the power distribution board

Power switch circuit

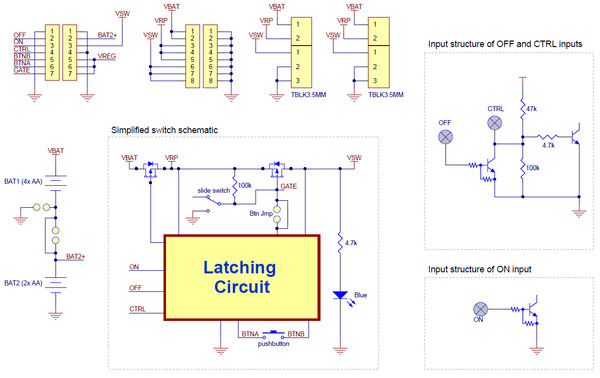

By default, the on-board pushbutton can be used to toggle power: one push turns on power and another turns it off. Alternatively, a separate pushbutton can be connected to the BTNA and BTNB pins and used instead. Multiple pushbuttons can be wired in parallel for multiple control points, and each of the parallel pushbuttons, including the one on the board itself, will be able to turn the switch on or off.The latching circuit performs some button debouncing, but pushbuttons with excessive bouncing (several ms) might not function well with it.

For proper pushbutton operation, the board’s slide switch should be left in its Off position. (Sliding the switch to the On position will cause the board power to latch on, and the switch must be returned to the Off position before the board can be turned off with the pushbutton.)

Alternatively, to disable the pushbutton, you can cut the button jumper labeled Btn Jmp; this transfers control of the board’s power to the on-board slide switch instead. A separate slide or toggle switch can be connected to the GATE pin and used instead.

More advanced control options are available through the button connection pins and four control inputs:

| PIN | Description |

|---|---|

| BTNA | Connect through momentary switch to pin “BTNB” for standard push-on/push-off operation. Connect through momentary switch to ground for on-only operation. |

| BTNB | Connect through momentary switch to pin “BTNA” for standard push-on/push-off operation. |

| ON | A high pulse (> 1 V) on this pin turns on the switch circuit. This pin only functions when pushbutton operation is enabled (i.e. the button jumper has not been cut). |

| OFF | A high pulse (> 1 V) on this pin turns off the switch circuit (e.g. allowing a powered device to shut off its own power). This pin only functions when pushbutton operation is enabled. |

| CTRL | With pushbutton operation enabled, this pin directly determines the state of the switch circuit. A high pulse (> 1 V) on this pin turns on the switch; a low pulse (e.g. driving the pin low with a microcontroller output line or pushing a button connected from this pin to ground) turns the switch off. Leave this pin disconnected or floating when not trying to set the switch state. Note that this pin should not be driven high at the same time the “OFF” pin is driven high. |

| GATE | With pushbutton operation disabled (button jumper cut), this pin controls the state of the switch circuit: driving it low turns the switch on, while letting it float turns the switch off. Connect through slide or toggle switch to ground for on/off operation. Leave this pin disconnected or floating for proper pushbutton operation. We recommend only ever driving this pin low or leaving it floating; this pin should never be driven high while the slide switch is in the “Off” position. |

Power distribution

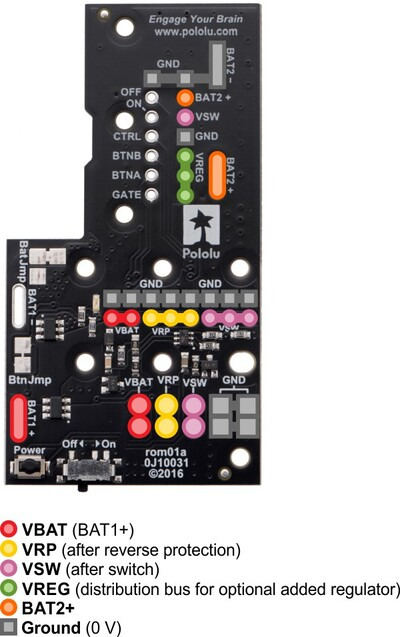

The diagram below shows the layout of the power distribution buses and access points on the board.

|

- VBAT is connected to the battery contact labeled BAT1+ and provides a direct connection to the battery supply. By default, VBAT is the high side of all six of the chassis’s AA battery cells in series, although this can be reconfigured with the battery jumper (see below).

- VRP provides access to the battery voltage after reverse-voltage protection.

- VSW is the battery voltage after reverse protection and the power switch circuit.

- VREG is not connected to anything by default, but along with the adjacent ground and VSW pins, the VREG pins provide a good place to connect an optional voltage regulator. For example, adding a D24V5F5 step-down regulator would make a regulated 5 V supply available for a microcontroller and other electronics on your chassis.

- BAT2+ provides access to the high side of two AA cells in series. This can be useful if you reconfigure the board to provide two separate battery supplies as described below.

Battery supply configuration

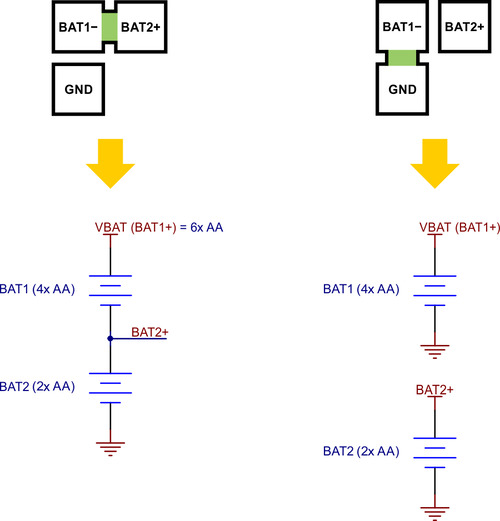

The power distribution board’s default configuration provides battery power, VBAT, from all six of the chassis’s AA cells in series (nominally about 7.2 V with rechargeable batteries or 9 V with alkaline batteries). However, the board’s battery jumper, labeled Bat Jmp, allows you to reconfigure the battery connections to provide two independent supplies: BAT1, with 4 cells in series (nominally 4.8 V rechargeable or 6 V alkaline), and BAT2, with 2 cells in series (nominally 2.4 V rechargeable or 3 V alkaline). Cutting the connection between the BAT1− and BAT2+ pads separates the two sets of batteries, and using solder to bridge the BAT1− and GND pads establishes a common ground between the two new supplies.

|

Warning: Do not bridge the BAT1− and GND pads without first disconnecting BAT1− from BAT2+. Failing to do so could create a short circuit across the BAT2 batteries.

Simplified schematic diagram

|

This schematic is also available as a downloadable pdf (110k pdf).

Enter the code in the box below: