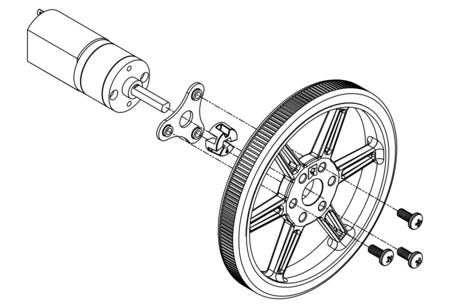

Pololu Multi-Hub Wheel w/Inserts for 3mm and 4mm Shafts - 80×10mm, Black, 2-Pack

These versatile wheels use interchangeable collets to tightly grab a variety of different common motor shafts, including the 3mm D-shafts on our micro metal gearmotors and mini plastic gearmotors and the 4mm D-shafts on our 20D metal gearmotors and 25D metal gearmotors. The wheels are 80 mm in diameter with 10 mm wide silicone tires, and they are available in black or white.

Four different collet inserts are included per wheel, allowing the wheel to work with four different shaft types: 3mm D, 3mm round, 4mm D, and 4mm round. The collet inserts slide easily onto their intended shafts and then clamp down as they are compressed into the wheel disc, resulting in a fit that is much tighter than can be achieved with similar press-fit wheels. The combined thickness of the collet and collet plate is approximately 6 mm, so we recommend you use this wheel with motors that have shafts that are at least 7.5 mm long.

This product is a pair of black 80×10mm wheels, and it consists of two sets of the following parts:

- silicone tire

- black ABS wheel disc

- four black ABS collet inserts:

- collet for 3mm D-shafts

- collet for 3mm round shafts

- collet for 4mm D-shafts

- collet for 4mm round shafts

- threaded metal collet plate

- three 7mm-long M3 screws

Using The Wheels

|

|

Installing the Pololu Multi-Hub Wheel on a motor shaft |

|---|

- Insert the motor shaft through the hole in the middle of the collet plate, making sure that the protrusions around the three threaded holes are facing out, away from the motor. Warning: these protrusions can be sharp!

- Slide the appropriate collet onto the motor shaft, making sure that the embossed digit (i.e. the “3” or “4”) is facing out, away from the motor.

- Slide the wheel on to the motor shaft with the embossed Pololu logo facing out, away from the motor, and press it onto the collet firmly, which will cause the collet to start squeezing down on the shaft. If you have the collet or wheel backward, the collet will not fit into the hole in the wheel.

- Insert three M3 screws through every other hole in the wheel and start screwing them into the threaded holes in the collet plate. Tighten each screw a little at a time so the wheel is pulled onto the collet evenly. For typical shafts, you will be able to tighten until the collet plate is almost flush with the back of the wheel, and the front of the collet is almost flush with the front of the wheel. If your shaft is a little larger than nominal, the collet might not press as far into the wheel, and if your shaft is a little smaller than nominal, you can insert something like a small washer between the collet plate and the collet to let it push the collet even farther into the wheel (i.e. past flush). Be careful not to over-tighten the screws as this can strip the threading on the collet plate.

Note that it is possible to assemble the wheels with a little wobble, but if that is a concern in your application, you can adjust how you tighten the three screws to get it as lined up as you like. Alternatively, you can often also fix a wobble just by pushing hard on the rim of the wheel at place where it’s most out of alignment.

Specification

Dimensions

| Size: | 80 × 10 mm |

|---|---|

| Weight: | 23 g1 |

General specifications

| Shaft type: | 3mm D, 3mm round, 4mm D, 4mm round |

|---|---|

| Color: | black |

Notes:

- Per wheel, including tire.

Related Documents

Enter the code in the box below: