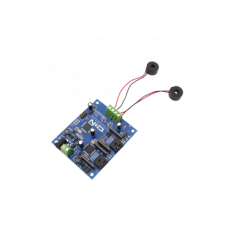

Industrial Current Monitor 2-Channel 5-20 Max Amps Wired Solid Core Dual Interface

NCD Current Monitoring Devices

Current monitoring has never been easier, or more accurate using XB2x Series Energy Monitoring controllers. The XB2x series includes off-board current sensing, designed to safely clamp over a single high-current wire for current consumption measurement applications. When properly calibrated, up to 6 high-current loads can be monitored simultaneously with a maximum error rate of 2%.

All XB2x series controllers include two communication ports compatible with our entire range of communication options, including Ethernet, Wi-Fi, Bluetooth, USB, or RS-232. For long-range, high-speed wireless communications, use the second communication port for industrial wireless applications supporting the Digi 802.15.4 and Digi S3B DigiMesh® communications modules. This device provides an ideal energy monitoring solution for most industrial and commercial applications at a low cost with unmatched accuracy.

Energy Monitoring Choices

Because we custom-build every controller, you have plenty of options. Simply choose the type of computer interface, the number of channels, type of sensor (split-core or solid-core), and your maximum current load (in amps). We will ship your controller pre-tested and pre-calibrated to 98% accuracy.

Tuning Ranges

When it comes to measuring a wide range of currents, there are many choices. In order to get the most accurate readings, you need to select exactly what you need and nothing more. Don’t be alarmed to see a 100 amp sensor on our web site offered with a 10 Amp measurement range. We do this for the sole purpose of improving accuracy. The electronics and the firmware were tuned to operate in the 10-amp range.

If you need to monitor a 10 amp circuit, you should choose a 10 amp controller (not a 20 amp controller). While there is no difference in cost, there is a significant difference in resolution. A 10-bit sensor reading across a 20-amp range will have HALF the resolution per bit as a 10 amp sensor. For this reason, and for the best possible resolution per bit, we offer many tuning ranges.

Solid Core Sensors

You may have noticed we offer both split-core and solid-core sensor options. Solid-core sensors are ideal in applications where low-cost or tight spaces are required. Solid-core sensors are not able to clamp over existing wire; they require a wire to run through the sensor during installation of the wiring. Solid-core sensors are a great choice for new installations. Because the sensor does not “break apart” like a split-core sensor, it has a smaller size and a lower cost.

Split-Core Sensors

For installations that must be retrofitted to add current monitoring, split-core sensors are our most popular choice. Split-core sensors can clamp over existing wiring by breaking apart the sensor and snapping it in place over the wire. Split-core sensors are larger and more expensive, but the versatility and ease of connection make them extremely popular.

Connection Options

Connecting sensors to a controller usually involves connecting two wires to the screw terminals of a controller. However, our SCT013 sensor includes a plug and a jack, reducing installation time.

Inductive and Resistive Loads

Unlike competing products, we do not gloss over the difficulties in monitoring highly inductive loads, such as motors, pumps, and other electrically noisy devices. We spent months developing algorithms that provide an excellent balance of speed and accuracy, whether you are monitoring resistive loads or inductive loads. Because of the difficulties in measuring inductive loads, our (free) Base Station software can be used to help fine-tune the calibration values to provide a more accurate measurement, further reducing the error rate to less than 2% for the most demanding loads.

Software

To get started quickly, use our free Base Station software. Base Station will have you monitoring energy in minutes, offering direct compatibility with your favorite communication technology (excluding Digi Wireless technologies). We highly recommend at least one USB interface in case you run into problems. Base Station and a USB interface can help get you connected fast!

Expandability

NCD Energy Monitoring controllers are designed with expandability in mind. Each controller includes two on-board I2C expansion ports, making it easy to expand to our complete line of I2C sensors, FET controllers, PWM controllers, and I2C relay boards.

Details

NCD Energy Monitoring controllers are rated for use with AC ONLY and will not work with DC loads. We have not yet completed 3-phase testing, but preliminary results are very hopeful. NCD Energy Monitoring controllers require 1.5 seconds to evaluate each channel. Therefore, a 6-channel controller will require 8 seconds to return a result for all channels. Sensors and controllers are designed to work together; it is NOT POSSIBLE to mix sensors to monitor different load sizes with a single controller. Mismatching sensors and controllers can result in permanent damage to the controller.

Users should avoid extending the cable of the current sensor as much as possible. Extending the wires may decrease accuracy.

Our tuning electronics can accept up to 5% current above the rated range, exceeding 10 amps + 5% for an extended period of time may cause damage to the tuning electronics or the CPU on our controller.

Off-board current sensors have a minimum load requirement of 1% of the total rating of the sensor. Failure to meet the minimum load requirements will significantly reduce accuracy. Please see minimum load requirements below.

Sensor |

Rating |

Type |

Connection |

Tuned Range (Amps) |

Minimum Load |

|---|---|---|---|---|---|

| DLCT27CL20 | 24 | Solid Core | Two-Wire | 5, 10, 15, 20 | 240mA |

| OPCTL16AL | 100 | Split Core | Two-Wire | 10, 20, 30, 50, 70, 100 | 1 Amp |

| SCT013 | 100 | Split Core | 3.5mm Jack | 10, 20, 30, 50, 70, 100 | 1 Amp |

| OPCTL38AL | 100 | Split Core | Two-Wire | 100 | 1 Amp |

| 150 | 150 | 1.5 Amps | |||

| 200 | 200 | 2 Amps | |||

| 250 | 250 | 2.5 Amps | |||

| 300 | 300 | 3 Amps | |||

| 400 | 400 | 4 Amps | |||

| 500 | 500 | 5 Amps | |||

| 600 | 600 | 6 Amps |

Choose Any Two Communication Modules

NCD current monitoring controllers support many communication options. With a dual interface, choose any two of your favorite communication technologies. Choose from USB, RS-232, Ethernet, WiFi, Industrial Wireless, or more.

XBee® is a registered trademark of Digi International. www.digi.com

802.15.4 Long-Range Wireless

Use 802.15.4 Communications if you require industrial strength long-range wireless communications. 802.15.4 is a point-to-point wireless standard, allowing fast communications. The wireless protocol acts as a long-distance wireless serial port, allowing wireless operation with no modification to software.

900HP-S3B Industrial Wireless Mesh

Long-Range Wireless Mesh networking is our favorite of all wireless communication technologies. This communication module will hop data from one location to another to reach its intended destination. Data hopping is a integrated feature of this communication technology, users do not need to do anything other than make sure wireless modules stay within hopping range of each other. We use the Digi 900HP-S3B module in our products, as this is the best the industry has to offer. With a 2 mile range between modules and up to 8 hops, it is possible to cover 16 miles of wireless territory using this technology. Using high-gain antennas, this module is capable of communicating to a remote module up to 28 miles away.

Bluetooth

Bluetooth is a easy way to add wireless communications to the NCD Industrial product line. The Bluetooth communications option acts as a transparent serial port between your computer and NCD devices. Simply pair the device with your computer and access the device through the COM port that is associated with the Bluetooth communications module.

Ethernet TCP/IP

Control NCD devices using standard Ethernet TCP/IP communications. Simply open a socket and send and receive TCP/IP data to control our devices. Our Ethernet TCP/IP Communication modules feature the Lantronix XPort communications module, the best in the industry. The Lantronix XPort module is an industrial workhorse that we have trusted for many years.

RS-232 Serial

NCD RS-232 Serial Communication modules make it easy to integrate the worlds most prolific communication standard. Easily interface to desktop PCs and laptops for easy control via standard serial commands. Most NCD devices typically default to 115.2K Baud; however, older low-cost devices implement 9600 baud data rate as the predominate standard.

USB

Our USB interface module makes it easy to control our devices using the USB port. Simply plug into any available USB port and start controlling our devices using standard serial commands. NCD USB Interface modules feature genuine FTDI USB to Serial Converter Chips, the very best in the industry.

WiFi TCP/IP

Control NCD devices using standard WiFi TCP/IP communications. Simply open a socket and send and receive TCP/IP data to control our devices. NCD WiFi communication modules are manufactured by Microchip, the world leader in microcontrollers.

ZigBee® Wireless

ZigBee® wireless communications is a popular standard among our customers. The wireless protocol acts as a long-distance wireless serial port, allowing wireless operation with no modification to software.

Features

- Current Monitoring with Dual XBee® Interface

- Compatible with Select Digi XBee® Wireless Modules

- Ethernet, Bluetooth, Wi-Fi, USB, and RS-232 Interface Options

- 2 Energy Monitoring Input Channels

- Options for up to 20 Amp Monitoring per Channel

- Solid-Core Off-Board Current Sensors

- 2% Max Error Rate for Resistive Loads

- May Be Calibrated for Inductive loads or Higher Accuracy

- 1.5 Meter Cable between Sensors and Controller

- Dual On-Board I2C Expansion Ports for Unlimited Expansion

Enter the code in the box below: