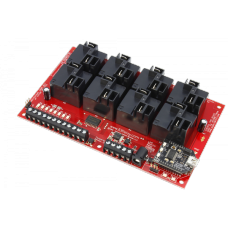

Reactor Sensor Controlled 8-Channel High-Power Relay Board + 8-Channel 8-Bit ADC

8-Channel Sensor Controlled High-Power Relays

This 8-Channel High-Power Reactor Relay Controller makes it easy for sensors to directly control external lights, motors, and other high-power electrical devices based on environmental actions or conditions. Use external sensors to activate relays for a pre-set time period. A single external sensor is capable of controlling multiple relays or relay sequences based on your configuration. Use a computer to configure the Reactor. Once configured, Reactor works stand-alone, or in combination with a PC, depending on your application requirements. Reactor is compatible with many popular communication technologies, providing a upgrade path should your needs change in the future. Mechanical Relays are an ideal for choice for most users because of their long-life and low cost. Inductive loads such as Motors, Valves, Pumps, Solenoids, and Large Transformers (including Fluorescent Lighting) will require external induction suppression capacitors to reduce interference to acceptable levels.

Reactor Relay Control

Sensor Controlled Relays Expand Automation WITHOUT Programming!

Intelligent Switching without a Computer is the foundation of the Reactor Series relay controllers. Reactor connects the real world to the electronics world, making it easy to configure and control real-world devices for simple automation tasks.

Reactor Automation Applications

Reactor can activate a light when it gets dark outside. Reactor can close a door that has been left open too long. Reactor can activate a heater to help maintain temperature. Reactor can turn on a light for 10 minutes if motion is detected. Reactor can water your crops when the soil moisture becomes too dry.

Configure Once, Automate Forever!

Reactor controllers are configured using our Free Base Station Software. Our simple GUI interface makes it easy to configure simple automation tasks with a point and click interface. Set parameters to activate relays within user-defined limits. Trigger timers, counters, and relay sequences with just a few clicks.

Once configured, the Reactor CPU will constantly monitoring external sensors using 8 analog inputs. When sensors reach pre-set limits, relays will be activated according to your configuration. Reactor is commonly used as a thermostat, motion activated light controller with a programmable timer, an automatic garage door closer, and much more.

Who’s Qualified to Use the Reactor Series?

Some computer skills are required. The Reactor series controllers do not require programming, simply configure the device with our Free Base Station Software. While programming is not required and simple functions can be done rather easily with basic computer skills, complex events may be possible with experimentation.

Sensors

The Reactor series controllers include 8 analog inputs, capable of reading switches, resistance changes, or voltages from 0 to 5VDC. Higher or lower voltages will damage the Reactor controller, so care must be taken not to exceed the voltage limits on the Reactor inputs. We offer many sensors to help get you started, including temperature sensors, light sensors, current sensor, and magnetic proximity sensors. You can connect your own sensors to the Reactor if we don’t offer what you are looking for. The Reactor configuration will control how the sensor affects the relay.

Complex Automation through Experimentation

Don’t be afraid to experiment with Reactor. Some complex automation can be achieved by experimenting with Reactor settings. Of course Reactor is capable of triggering relays, but did you know that Reactor can also trigger events? Relays can be associated with events, allowing you to play with all kinds of complex timing and counting settings. Events greatly expand the pallet of functionality available to Reactor.

Computer Controlled Relays

Software developers who need remote access to a Reactor controller will find themselves at home. The Reactor supports a very powerful computer-based command set, so it is possible for a computer to operate the relays and read sensor inputs. The computer can over-ride the Reactor decision logic, trigger events, and return control of the relays back to the Reactor Logic. Configuration settings are stored in files that can be loaded into other Reactor controllers.

Removable Communications Module

Once configured, Reactor controllers operate on their own, without a computer. Reactor will never lose its settings. In fact, the communication module can be removed from the Reactor controller and used to configure another Reactor controller. This helps keep costs down. If you choose to leave the communication module installed on the Reactor, your computer can monitor inputs and control relays.

Communications Module Options

Reactor supports many communications technologies, including USB, RS-232, Bluetooth, Ethernet, and Industrial Wireless. We recommend the USB option, as Reactor focuses on automation, and is frequently used without any communications module once configured. Nonetheless, please feel free to choose the technology that best suits your needs as our Base Station software supports them all. Additional accessories will be required when selecting the KFX Key Fob option, as the Key Fob module must also be configured and does not include any remote controls.

802.15.4 Long-Range Wireless

Use 802.15.4 Communications if you require industrial strength long-range wireless communications. 802.15.4 is a point-to-point wireless standard, allowing fast communications. The wireless protocol acts as a long-distance wireless serial port, allowing wireless operation with no modification to software.

Bluetooth

Bluetooth is a easy way to add wireless communications to the NCD Industrial product line. The Bluetooth communications option acts as a transparent serial port between your computer and NCD devices. Simply pair the device with your computer and access the device through the COM port that is associated with the Bluetooth communications module.

Ethernet TCP/IP

Control NCD devices using standard Ethernet TCP/IP communications. Simply open a socket and send and receive TCP/IP data to control our devices. Our Ethernet TCP/IP Communication modules feature the Lantronix XPort communications module, the best in the industry. The Lantronix XPort module is an industrial workhorse that we have trusted for many years.

RS-232 Serial

NCD RS-232 Serial Communication modules make it easy to integrate the worlds most prolific communication standard. Easily interface to desktop PCs and laptops for easy control via standard serial commands. Most NCD devices typically default to 115.2K Baud; however, older low-cost devices implement 9600 baud data rate as the predominate standard.

USB

Our USB interface module makes it easy to control our devices using the USB port. Simply plug into any available USB port and start controlling our devices using standard serial commands. NCD USB Interface modules feature genuine FTDI USB to Serial Converter Chips, the very best in the industry.

WiFi TCP/IP

Control NCD devices using standard WiFi TCP/IP communications. Simply open a socket and send and receive TCP/IP data to control our devices. NCD WiFi communication modules are manufactured by Microchip, the world leader in microcontrollers.

20-Amp SPDT Relay Option

This controller is available with a 20-Amp relay option, allowing control of high-power loads up to an absolute maximum of 240VAC at 20 Amps. Ideal for high-power switching applications, this relay should never be used for low-power signals. The 20-Amp relay is of the SPDT variety, which provides Common (C), Normally Open (NO), and Normally Closed (NC) connections. Common is connected to NC when the relay is off. Common disconnects from NC and connects to NO when the relay is activated. This relay uses .250″ Quick Connect terminals (optional accessory) to connect to the top side of the relay. The relay is molded with COM, NC, and NO markings into the plastic.

30-Amp SPST Relay Option

This controller is available with a 30-Amp relay option, allowing control of high-power loads up to an absolute maximum of 240VAC at 30 Amps. Ideal for high-power switching applications, this relay should never be used for low-power signals. The 30-Amp relay is of the SPST variety, which provides Common (C) and Normally Open (NO) connections. Common has no connection when the relay is off. Common connects to NO when the relay is activated. This relay uses .250″ Quick Connect terminals (optional accessory) to connect to the top side of the relay. The relay is molded with COM, NO markings into the plastic.

Features

- 8 On-Board Sensor Controlled Mechanical Relays

- Ideal for High-Power Switching Applications

- Choose Between 20-Amp SPDT or 30-Amp SPST Relays

- Stand-Alone Operation, Only Requires PC for Initial Setup

- 8 Analog Inputs Trigger Relays Based on User Configuration

- 8 Background Timers Offer Timed Relay Switching Functions

- 4 Rotation Counters Trigger Relays Based on Counting Values

- Use a Computer to Take Control of the Reactor Logic

- CPU Status LEDs Show Command Processing Activity

- Optional Key Fob for Long-Range Remote Operation

- Modular Communications Interface for Use with:

- USB, Bluetooth, WiFi, RS-232, Key Fob, or Ethernet

Enter the code in the box below: